Search

Wax is referred to as the “soft gold” of the industry. It boasts low-temperature fluidity, excellent wetting and dispersing properties, superior temperature resistance, and chemical inertness. Wax can be found in various aspects of daily life.

When the typical properties of wax cannot directly meet industry application requirements, deep processing and modification are needed. This includes processes such as molecular separation, isomerization, grafting, oxidation, micronization, and oil and water emulsification to produce specialized waxes with enhanced performance. Nearly a hundred types of specialty wax pe products are now used in fields such as pharmaceuticals, military, civil explosives, electronics, transportation, agriculture, chemicals, rubber and plastic processing, paper making, textiles, thermal storage materials, coatings and surface protection, controlled-release materials, precision casting, polishing materials, dye dispersion, ink printing, cosmetics, stationery, adhesives, and more.

Thermal and phase change storage materials — Through distillation technology, these waxes can be purified and their properties controlled. The resulting high-normal paraffin low-molecular waxes have the ability to undergo phase changes within specific temperature ranges, making them suitable for energy storage systems.

To improve the compatibility of wax with different resins, introducing functional groups is an effective method. Through chemical reactions such as esterification, etherification, amidation, and oxidation, specific functional groups can be introduced into wax molecules, thereby enhancing their compatibility and interaction with resins.

Introducing functional groups also paves the way for the aqueous formulation of industrial wax products. Through micronization or even nanonization, as well as critical powdering, low-temperature grinding, emulsification dehydration, and oil powdering methods, the low-temperature solid phase, aqueous phase, and oil phase dispersion properties of wax products can be improved.

For hot melt adhesives, their open time, nucleation speed, and service life are strictly influenced by the crystallization temperature, enthalpy change, and crystallinity of the wax products.

New energy battery pack sealing and overall solid sealing — Wax exhibits resin-like properties at low temperatures and can be recycled, making it a substitute for traditional epoxy resins. The widespread use of electronic components and integrated electronic boards in outdoor equipment makes the impregnation protection and moisture resistance of wax very important, requiring the wax film to be dense and not easily detached under external forces.

Specialty wax thermal materials have broad applications in irreversible thermal warning waxes, especially in high-voltage power grids. These waxes typically present as films with two significantly different colors, possessing good adhesion and flexibility.

Solid, high-isomer waxes exhibit volume changes due to variations in intermolecular forces at different temperatures, a property that can be applied in precision displacement thermal controllers.

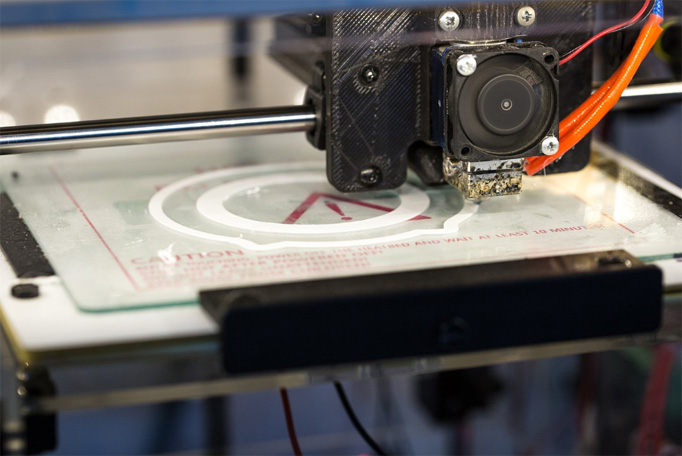

Additionally, wax can be used in metal protection, ink modifiers, 3D printing materials, and outdoor protection for cables and steel wires. For more information, please contact KH.